At 63 feet (19m) long and 13 feet (4m) wide the Vulcan could carry 200 people and their luggage. She joined the three existing passage boats plying the Forth and Clyde Canal between Port Dundas and Lock No.16, where passengers could embark on a steam boat for Leith.

Ice was a real problem on the canal. Being shallow the water could freeze very quickly, for example in December 1815 the company’s Resident Engineer reported that ‘it was again that by one night’s frost, that the Passage Boats could not Break it’. The ice would stop the boats or cause them to need extra horses to pull them. It could also damage the wooden boats and this led Sir John Robison, a member of the company’s Management Committee to propose an iron boat.

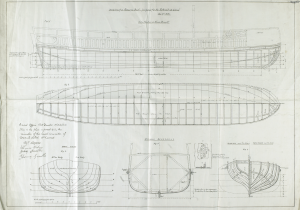

Glasgow-based former Boulton and Watt engineer Henry Creighton was commissioned to produce a design for the boat. Creighton based the hull on a design by Captain John Schank of the Royal Navy. By then in his seventies, Schank was an innovative Scot who specialised in designing boats for shallow waters. He had been responsible for the hull of the pioneering steamboat the Charlotte Dundas.

Possibly Creighton’s genius was in working out how to build the elegant hull shape Schank had sent him using iron instead of wood.

The Construction of the Vulcan

In October 1818 the contract for building the iron boat was awarded to a consortium of three men:

Thomas Wilson was an experienced boat-builder based at Faskine on the Monkland Canal. Wilson had never built an iron boat but his partners, brothers John and Thomas Smellie were blacksmiths and boiler-makers in the Coatbridge area.

The three men beat off competition from two prominent Glasgow iron founders to gain the contract by promising to build the boat from high quality imported scrap iron. They were given just five months to build the Vulcan!

The actual construction of the Vulcan was made possible by advances in the boiler-making trade. The hull plates were fitted flush edge-to-edge and riveted to overlapping ‘butt-plates’ inside. This was now standard practice in boiler construction where the quality of the seal was critical.

The iron plate for the boat was rolled at Calderbank Forge, less than a kilometre to the east of Faskine. This forge would soon become one of the biggest iron works in Scotland but in 1819 it was a small affair with water-powered tilt hammers and a rolling mill.

Iron plates of three different thicknesses were brought from Calderbank to Faskine. They were then re-heated before being beaten to shape and pierced for the rivets. The plates were then hammered and riveted onto a frame of angle iron that they had forged themselves. This is where the Smellies’ expertise as boilermakers was crucial.

Thomas Wilson later wrote, ‘there was no angle iron in those days, nor any machinery, except an old fashioned piercing machine purchased from Mr Robt. Baird, Old Basin, a cast iron grooved block to form the ribs, [and] a smith’s fire.’ Construction lasted through the winter of 1818-19 and into the following spring. Not surprisingly the Vulcan wasn’t ready on time. Instead of carrying her first passengers in May 1819 she was not ready until near the end of the summer season. However once in service she proved a great success.

The hull plates were fitted so well that it was remarked in 1820 that her bilge pumps ‘have hardly required to be used’. Even 44 years later the son of her first master could say, ‘it is really surprising to see the hull of her looking so well, and that she is quite tight.’

An 1818 plan of the Vulcan signed by Thomas Wilson and the Smellie brothers. © National Records of Scotland

The Layout of the Vulcan

The Vulcan had two cabins, one for first class passengers and another for steerage with entrances at opposite ends of the boat. These were not the doors you see today which are recent additions.

The middle section of the boat between the cabins housed the captain’s room, servant’s lockers and toilets. Refreshments were available although there had been complaints about the quality of the liquor served on board the boats!

On docking at Lock 16 in Falkirk passengers could expect to be greeted by a melee of unofficial ‘porters’ offering to convey their luggage up the hill to the Union Canal where they could join another boat to take them to Edinburgh. Alternatively they could join one of the Edinburgh stagecoaches that met the boats at Falkirk.

The Vulcan continued to carry passengers until the 1830s when she was converted into a cargo boat. She spent the rest of her days travelling the canal network and is even said to have plied on the Clyde with a mast and sail. Not broken-up until 1873, the Vulcan’s long life reflects the skill of her builders and of the Lanarkshire boilermakers whose techniques had made this pioneering boat possible.

The Vulcan at Summerlee

The replica you see today was designed by Fred M. Walker of the National Maritime Museum and built from mild steel by apprentices of British Shipbuilders at Govan. She was probably the last vessel built on the Clyde using traditional riveting techniques and in 2014 the replica installed on the Gartsherrie branch of the Monkland Canal at Summerlee. We hope you enjoy your visit aboard the Vulcan.

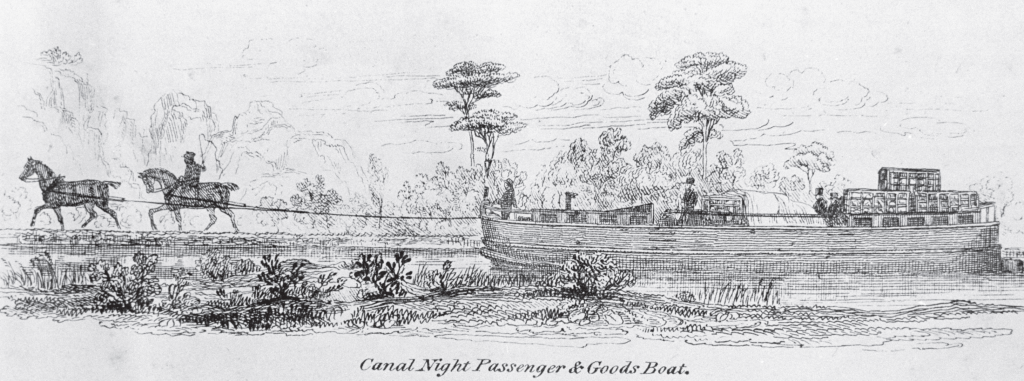

A horse drawn passenger boat similar to the Vulcan. © East Dunbartonshire Council. Licensor www.scran.ac.uk

How to FIND the Vulcan and summerlee museum

- We are situated just to the west of Coatbridge town centre, about 20 minutes from Glasgow city centre by train from Queen Street station low-level to Coatbridge Sunnyside, then a 10 minute walk.

- Or 50 minutes from Glasgow Central to Coatbridge Central via Hamilton and Motherwell and a five minute walk.